Well, it wasn’t easy but we got the Dozer moved to our land. That’s the good news; let me fill you in on the rest. (more…)

Hey guys, just wanted to keep you updated on the progress for the John Deere 1010 dozer. A few days ago I had a friend come over (Thank you Brian!) and help me diagnose the electrical problem as a faulty wire to the starter. That sucker was iced in there bad, and with the loader arms on we had a heck of a time getting it out. 4 hours of time, to be exact.

Today I was able to replace the wire and reinstall everything. It was a little warmer out today, so that helped things go a little quicker – plus I knew what I was doing. After replacing everything, the engine turns over wonderfully – much faster than it had previously. That makes sense, when you think about it. Less resistance because of a better connection equals more electricity to the starter motor.

Unfortunately, I still was unable to get it to fire. I had tried turning it over with the fuel injectors cracked; after replacing the fuel filters I’m supposed to bleed the air out of the system by cracking the injectors. With them open, cranking the engine draws fuel up and purges the air in the system. Unfortunately, this little dozer is still having fuel system problems.

I cracked open the bleeder on the fuel pump and found that it’s nicely full of fuel. However, with the fuel line (that goes to the injectors) off the pump, I tried to crank the engine. If the pump is working as it should, fuel should spray everywhere due to the pressure. It did not. So therein lies my problem with the fuel system. For one reason or another, the fuel pump is not delivering enough pressure for the engine to fire.

I suspect that there is ice in the pump from moisture in the old fuel. There has been ice in just about every component that I have disassembled so far, so I have no reason not to think that. That, and I’m really hoping that it’s just ice. Parts for this old dozer are hard to come by, and a new fuel pump is upwards of $900. Next time I get a chance to work on the dozer I will be attempting to thaw out the fuel pump, and hopefully I’ll rectify this problem.

Just over two years ago my father passed away, and he left behind his John Deere 1010 crawler tractor. I wish I had taken the opportunity to learn more about it when I could. Now I’m in the predicament of learning about it while I attempt to repair it. During the winter. (more…)

Hey guys! This winter has been pretty brutal for us; not when you compare it to the winters of the past, but still. Whether it’s been the below zero cold, or the (moderate) amount of snow, or fixing vehicles outside with no garage, or moving Dad’s tools and possessions to our house – really the list goes on. To sum up my point, I haven’t had a chance to build or film any woodworking projects this winter. And that’s really bummed me out. (more…)

As soon as we started talking about building our kitchen cabinets I envisioned a bookmatched slab of some species for the countertop. We ended up choosing maple because the sawmill had it in stock, it fit our required dimensions, it was a good price, and it had a cool story.

A few years back when we had that massive wind storm we were still living in town. Trees were down everywhere, and it was chaos. That happened the week before I started framing the house. Often, Bre would encourage me to take a few days off from building to go gather trees people were putting out at the curb. Had this occurred any other time than when I had just started building we could have had substantial pile of material for the eventual sawmill.

Alas, I did not. I was too eager to build, too ambitious to finish the house. That said, we did try to get a log on a few occasions. On one such instance, we found a maple tree listed on Craigslist that had come down in the storm. It was three blocks from our house, so we went to take a look. By the time we had gotten there it was already gone. Flash forward 2 years and we come to find out that the guy at the sawmill had grabbed it before we could. So, now that tree is a part of our new house in our countertop.

As far as the countertop construction goes, it was fairly straightforward. Since we wanted to bookmatch the slab, we ripped it to the width we needed while preserving the mirror of the joint. Once the two slabs had been jointed and glued into one big slab we could cut the final widths from the outside of the slab and also cut it to length.

There was a pretty significant twist in this log, and since we were bookmatching the slabs it would appear at offsetting corners of the slab. The only way to remove this twist was during the flattening. In order to flatten the slab, I had to go and buy a router and make a flattening sled to run over the slab. It worked well with a straight bit, but due to the twist we lost almost half of the thickness in places.

I was concerned that having a thinner countertop would both look silly and be weak, so to remedy that we used a 3/4″ piece of plywood as a substrate and then fashioned an apron around the front edges to cover the plywood. This gives the appearance of a thicker slab. In order to attach the apron to the countertop, I drilled pilot holes and countersunk them to screw the apron to the countertop. In the front this is no big deal and we could fill the holes in after screwing with some plugs cut from the offcuts of the countertop. In the end grain where we screwed the side apron, we had to provide slotted pilot holes to allow for wood movement.

We’re super pumped to finally be done with this project. It’s been weighing on me for a few months now, so it’s a relief to be finished. Washing dishes in a functioning sink is taken for granted, and it feels great to be able to do that again.

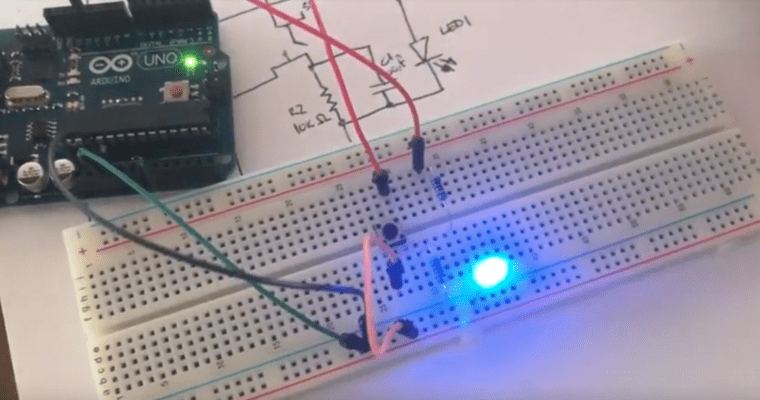

Yesterday’s video was a lot of fun as I began the process to learn and understand the procedures for effectively using an Arduino. Today’s project wasn’t necessarily as productive. (more…)